Here’s How to Improve your Bus AC Cooling This Summer

Are you a bus operator struggling to get the most out of your bus’ air conditioning system? Our comprehensive guide will help you to improve your bus AC cooling and ensure a great customer experience. From cooling your passenger cabin before your passengers board the bus, and practical tips on maintaining your bus AC unit to troubleshooting common problems, this guide encompasses everything you need to get the maximum cooling from your AC unit during the peak summer season.

With summer at its peak, bus ACs have become the most important part of any bus journey. To ensure that your passengers have a comfortable and pleasant travel experience, ensure the air conditioning unit performs at its optimum level. This is the need of the hour for any bus operator.

Let’s face it, if the cooling of your AC is inadequate, you will end up with dissatisfied customers and poor reviews on platforms like RedBus, ultimately affecting your business’s reputation and profitability.

On this note, you can also check out our ninja guide to improve RedBus ratings. You can find a slew of strategies to attract more positive reviews and increase your visibility on the RedBus platform thereby maximizing bookings.

Also Read: Bus Travel | Long Weekend Travel Trends: Abhibus Insights 2024

Ideal AC Temperature

According to AK Mandal, Head of Service Engineering at India’s leading bus AC manufacturer JTAC, the ideal temperature for a bus AC is between 22°C and 24 °C.

“We ideally suggest operators to maintain the bus AC at 24°C. Everyone has different comfort levels with temperature. Universally, 24°C is considered to be the optimum temperature for ACs as it accommodates everyone’s temperature sensitivities,” he told Coach Builders India.

Familiarize Yourself With the AC CAB Cab Controller

Before we go about the ways to improve your bus AC cooling, let’s familiarize ourselves with the AC CAB Controller. This unit is generally in the driver’s dashboard and the brain of the bus AC cooling unit.

For this article, we will be using a JTAC CAB Controller since most buses in India use JTAC ACs.

Also Read: The 10 Best Electric Buses in India With Range

Tips to Improve Your Bus AC Cooling During Summer

On a hot summer day with temperatures crossing south of 40°C, every passenger expects to board a bus that is already cool inside. This means you need to ensure that your bus’ passenger cabin is already cool by the time boarding starts.

This is how you can achieve this:

- First of all, the AC needs to be switched on at least 20-30 minutes before passengers board the vehicle

- Switch on the Power Button on the AC Controller (8)

- Then, switch on the Cooling Button (Clutch) (2). The AC compressor will not start unless the Clutch button is switched on

- Set the temperature to 16°C using the Temperature Cap Settings Buttons (1).

- The Current Cabin Temperature will be visible in LED Display (6). Set the Capped Temperature to 22°C (7)

- There are three fan speed settings – Low, Medium, and High. Set the fan speed to High using Fan Speed Button (4). Fan Speed will be visible in LED Display (5)

- If possible, open the roof hatch of the bus for 10 minutes to let the warm air out.

Ideally, it should take about 20 minutes to cool the heated passenger cabin. Once the passenger cabin comes down to ~22-23°C or after passengers board the bus you need to ensure that the passenger cabin temperature is maintained at 24°C throughout the journey.

This is how you can achieve this:

- Set the cabin temperature to 24°C using the Temperature Cap Settings buttons (1)

- Lower the Fan Speed to Medium using the Fan Speed Button (4).

- Fan Speed will be visible in LED Display (5).

The AC Button (Clutch) (2) should be switched on at all times. Most drivers have the habit of switching it on and off intermittently but this is a practice that should be avoided.

Once the Capped Temperature is set, the AC unit doesn’t need manual intervention, the auto cut-off feature will ensure that the set temperature is maintained throughout.

Also Read: List of Made in India Hydrogen Buses Empowering Sustainable Mobility

Should the Bus AC be Kept Switch-On During Food Halts?

It depends. You will consider that not all passengers deboard the bus at pit stops or food halts. Some prefer to stay on the bus.

During peak summers, when temperatures cross the 40°C threshold, it can get unbearably hot and suffocating inside the bus if the AC is switched off.

Hence, most reputed operators keep the bus AC switched on during stops.

Sure, running the AC does consume fuel, but the trade-off is increased customer satisfaction, which can be more rewarding than saving a few liters of diesel.

Bus AC Maintenance Manual

A well-maintained bus AC is the key to ensuring optimal cooling performance and passenger comfort. A timely maintenance schedule helps prevent breakdowns, reduces energy consumption, and extends the lifespan of the AC unit.

It not only contributes to reliable service and operational efficiency but can also save you from costly repairs.

Here’s how you can maintain it and improve your bus AC cooling:

- For a bus that clocks 500-700 km daily, the Grill Filter and the Coil Filter in the Return Air Filter Unit should be cleaned at least once a week. (Image 1)

- The Grill Filter is located inside the Grill of the Return Air Filter. (Image 2)

- The Coil Filter can be accessed after removing the Grill Filter. (Image 3)

Also Read: In Pics: The Evolution of Prakash Tourist Buses Over the Last 50 Years

JTAC Bus AC Troubleshooting

Error Codes in Cab Controller

The bus AC, like most machines, may encounter minor problems at times. These errors are typically displayed on the cab controller through a series of Error Codes.

The CAB Controller intimidates about minor glitches in the AC Unit through a series of Error Codes. Although it is advisable to not fiddle with the AC unit without technical supervision, we have detailed the list of ERRORS that JTAC AC CAB Controllers display:

| ERROR CODE | PROBLEM |

|---|---|

| ERR 01 | Low voltage |

| ERR 02 | High voltage |

| ERR 04/ERR HP | High pressure |

| ERR 08/ERR LP | Low pressure |

| ERR LT | Supply air sensor wire open / Clutch not ON |

| ERR 16 | Supply air sensor wire short / Clutch ON |

| ERR H | Return air sensor wire short / Clutch ON |

| ERR L | Return air sensor wire open / Clutch not ON |

JTAC Bus AC Error Codes

Troubleshooting options for the above-mentioned JTAC Bus AC Error Codes are listed below:

| ERROR CODE | TROUBLESHOOTING |

|---|---|

| ERR 01 | Check the Alternator output |

| ERR 02 | Check vehicle Alternator output |

| ERR 04 | Check the gas in the system, condenser fan, HP switch, and HP wire (78) |

| ERR 08 | Check the gas in the system, LP switch, LP wire (68) |

| ERR LT | Check wire No. 23 |

| ERR 16 | Check wire No. 23 |

| ERR H | Check wire No. 21 |

| ERR L | Check wire No. 21 |

Wrapping it Up

As long as the summer season persists the AC will continue to be the main concern of your passengers. For the best customer experience, you, as a bus operator, are bound to ensure that your AC performs efficiently throughout each bus journey.

If you follow the steps outlined in this article you will be able to improve your bus AC cooling and offer a more pleasant and efficient journey for passengers, even in the hottest days of summer.

Regular maintenance also plays a crucial role in ensuring that your bus AC operates efficiently, maintains optimal performance, and provides reliable cooling throughout its lifespan.

Additionally, driver training and awareness play a crucial role in maintaining optimal cooling conditions. Share these tips with your drivers and educate them on how to operate the bus AC during peak summers.

If you have any questions, let us know in the comments and we will update them in the article.

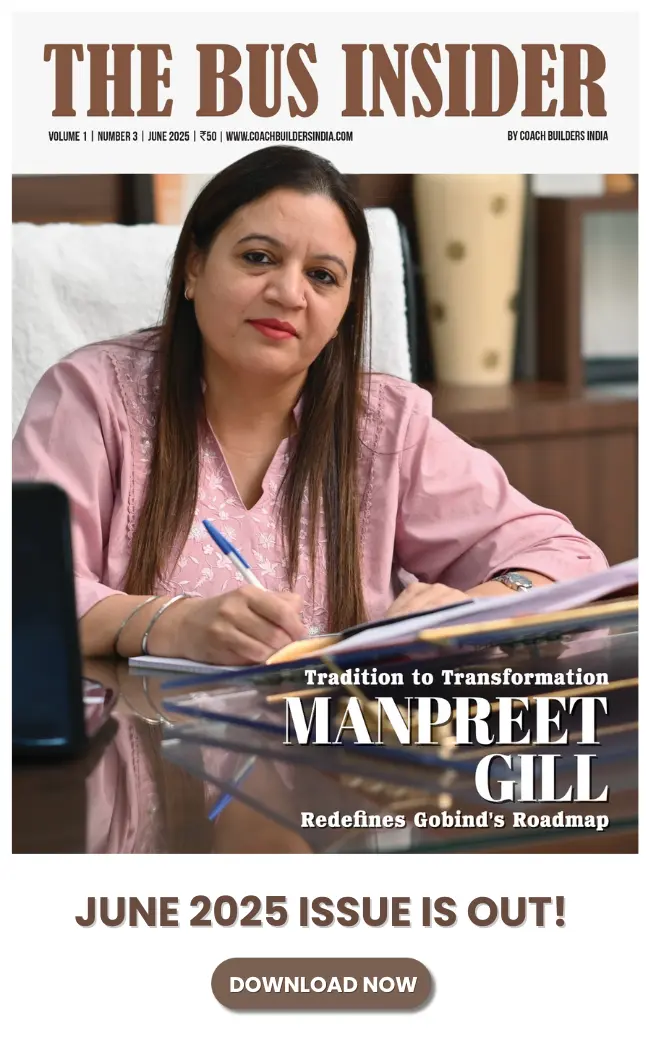

Catch the Latest Bus Industry Updates, Exclusive Interviews, Bus News, and International Bus News on Coach Builders India. Download the latest issue of the The Bus Insider magazine for industry insights.